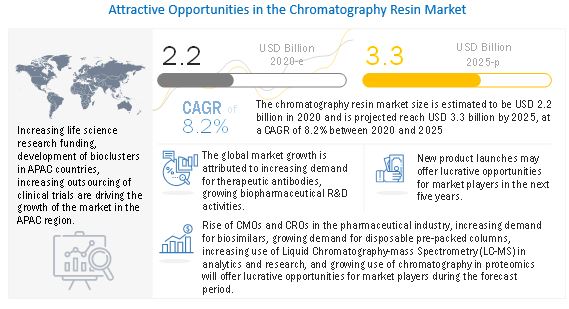

The report "Chromatography Resin Market by Type (Natural, Synthetic, Inorganic Media), Technique (Ion Exchange, Affinity, Hydrophobic Interaction, Size Exclusion, Multimodal), Application (Pharma & Biotechnology, Food & Beverage), Region - Global Forecast to 2025" The chromatography resin market is projected to reach USD 3.3 billion by 2025, at a CAGR of 8.2% from USD 2.2 billion in 2020.

♦ Download Detailed PDF Brochure

Impact of COVID-19 on Chromatpgraphy Resin Market

Although the COVID-19 pandemic continues to transform the growth of various industries, the immediate impact of the outbreak is still diverse. While a few industries will register a drop-in demand, numerous others will continue to remain stable and show promising growth opportunities (pharma & biotech). The chromatography resin market has witnessed significant growth previously. Due to the unexpected COVID-19 outbreak, the market will witness additional growth in 2020, owing to the increasing use of chromatography techniques in the approval of various drugs.

Currently, an increasing number of research activities are being performed to test the impact of COVID-19 on human bodies, as the outbreak has led to a crisis around the world. In addition, technological advancement and the increasing importance of chromatography in laboratories, forensic labs, and pharmaceutical R&D will enhance market growth during the forecast period.

♦ Inquiry Before Buying – https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=933

Natural polymer is the largest type for chromatography resin market in 2019

Natural polymer used in chromatography techniques is extracted from living cells such as plant and bacteria cells. Agarose, cellulose, and dextran are the natural polymers that are most commonly used as resins in chromatography applications. Chitosan is also used as a resin in a few ion chromatography applications. Most of these natural polymeric resins are polysaccharides. The major advantage of these natural polymers is their hydrophilic nature, as they have a large number of hydroxyl groups in their structure.

Affinity is estimated to be the largest technique in chromatography resin market between 2020 and 2025.

Affinity chromatography offers high selectivity, resolution, and capacity in most protein purification schemes. It has the advantage of utilizing a protein's biological structure or function for purification. As a result, purifications that would otherwise be time-consuming and complicated can often be easily achieved with affinity chromatography. The major applications of affinity chromatography include separation of a mixture of compounds, removal of impurities in the purification process, enzyme assays, detection of substrates, investigation of binding sites of enzymes.

Contact -

Mr. Aashish Mehra

MarketsandMarkets™ INC.

USA : +1-888-600-6441

Email: newsletter@marketsandmarkets.com

Visit Our Website: https://www.marketsandmarkets.com/